Bromosol is an advanced single component biocide that helps protect cooling towers and industrial water systems from biofilm. Bromosol’s high performance and simple and convenient use promote cost-effectiveness while addressing numerous macro-level needs.

One of the major challenges facing cooling towers and industrial water systems is surface waterbiofilm, which is generated due to the accumulation of microorganisms such as bacteria, fungi and algae.

Cooling tower biofilm is a well-known industry challenge, and so are most biocides that are commonly used to control it. Perhaps the most well-known and most commonly used oxidative biocide is sodium hypochlorite, which relies on chlorine chemistry as its main component. The alternative oxidative solution to chlorinated biocides is mainly bromine-based biocides. While chlorine-based biocides do exhibit certain effectiveness, they are limited and carry certain disadvantages. ICL’s Bromosol is designed to overcome these disadvantages – while also introducing several significant benefits.

A Distinctive Product

Bromosol is the product of a unique manufacturing process. Unlike other stabilized bromine solutions in the market, Bromosol is derived directly from elemental bromine, and therefore does not contain chlorine remnants. Based on the oxidizing power of bromine, Bromosol’s main distinction is that it is a single component solution. This sets it apart from two-component oxidative biocides, and makes it easier to operate and implement. From a cost-effective perspective, this characteristic has far-reaching implications. But it is also just the tip of the iceberg.

Superior to Sodium Hypochlorite

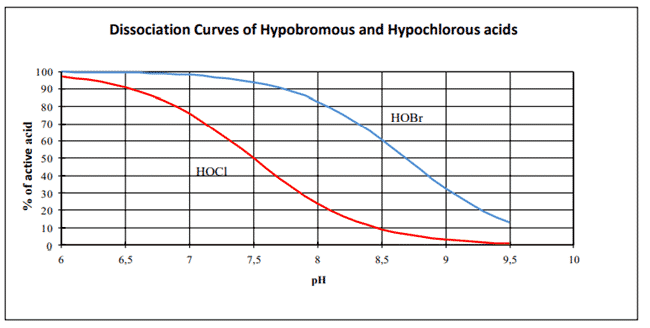

While sodium hypochlorite as a single component biocide can be used only in pH conditions below 7.5, Bromosol can be used throughout the entire pH range. In many cases at high pH conditions, when sodium hypochlorite is used, there will be a need to add higher biocidal solution volume into the water in order to compensate for the lower effectiveness. This will result in higher corrosivity that damages the cooling tower structure.

Bromosol is a bromine-based solution. When dealing with biofilm in neutral-to-alkaline conditions (pH 7 and up), hypobromous acid is a more effective microorganism eliminator than hypochlorous acid. Many cooling towers operate in neutral-to-alkaline environments.

In addition, the organic materials’ reaction to hypobromous acid creates compounds called bromamines, which act as effective biocide water treatments that control bacteria, fungi and algae over time. Bromosol’s extremely low volatility ensures that its active component remain in the water for much longer periods than hypochlorite-based biocides, thus controlling microbiological growth with added efficiency.

You may be interested in:

Flame retardants – Save lives!

From Pipe Blockage to Paper Mill Biofilm Treatment: The Story of Bactebrom®

Bactesperse®: The Invention that Defeats Bacterial Colonies

Proven Added Values

Currently, Bromosol is used extensively in cooling towers and industrial water systems. The results are highly satisfactory, which is not surprising, because Bromosol’s efficiency translates into immediate results.

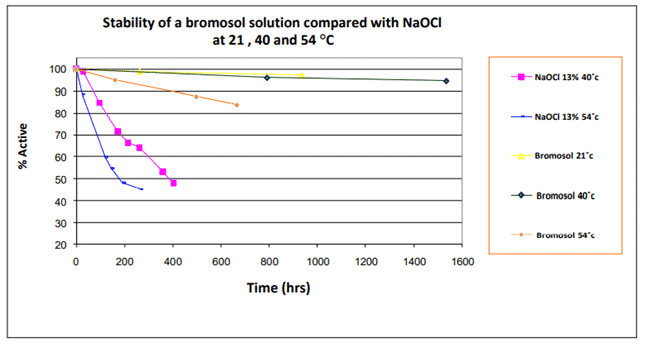

For starters, Bromosol’s low volatility and heightened effectiveness allow operators to administer it in smaller doses. Naturally, this makes Bromosol more cost-effective in comparison to other, less effective, biocides. Compared to sodium hypochlorite, Bromosol’s proven active substance stability leads to longer product shelf life, which supports small dose administration and reduces product waste.

As mentioned, low dosage may also lead to less corrosion, thus protecting cooling tower infrastructure. In fact, Bromosol has demonstrated little to no reactivity to corrosion inhibitors used in cooling towers. Its scale inhibitor reversion rates are relatively low, as well. In comparison, the powerful impact of sodium hypochlorite, which is usually used in large doses, promotes surface scale and corrosion.

Bromosol complies with stringent European regulations pertaining to chemicals and biocides. Bromosol also adheres to health requirements, specifically regarding bacteria that can cause harm to humans. For example, Legionella pneumophila, a bacterium that causes Legionnaire’s disease (Legionellosis), has been known to be a major concern in water systems since it poses a potential health risk. Bromosol’s strong oxidation disrupts bacterial activity by destroying their membranes, and can therefore control Legionella pneumophila.

Overcoming the Biofilm Challenge – the Smart Way

ICL’s R&D recognizes the industry’s current production, regulatory and financial needs regarding cooling towers and water systems. Bromosol was developed as a direct response to these needs. As industries continue to evolve, ICL’s R&D team is determined to continue providing solutions that can help drive production, reduce costs and contribute to a sustainable future. In this respect, Bromosol is an ideal solution.

Many biocides can handle biofilm, but Bromosol exhibits extremely high-performance levels, and is designed to accommodate a variety of macro-level needs. It’s the smartest, most comprehensive solution in the fight against cooling tower biofilm.